Welding Cables Double Insulated, Extra Flexible, Orange and Black Jacket

| Price: |

0.3~24.0 USD |

| Payment Terms: |

T/T,L/C,WU |

| Place of Origin: |

Henan, China (Mainland) |

Product Detail

Model No.:

welding cable

Production Capacity:

50000m/week

Delivery Date:

15days for one container

Type:

Low Voltage

Jacket:

Rubber

Brand Name:

Aodian

core:

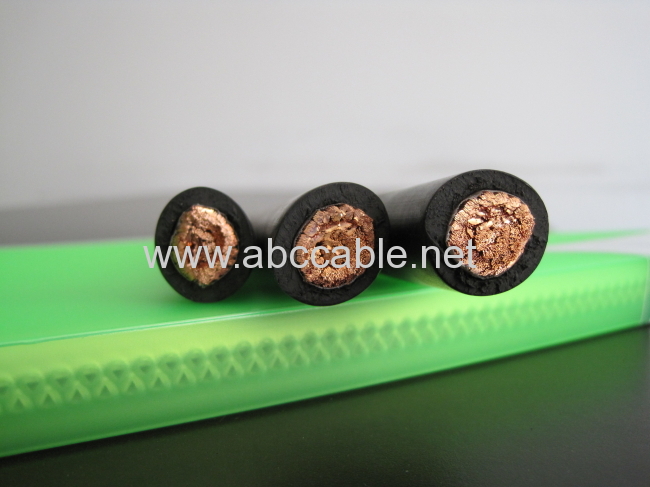

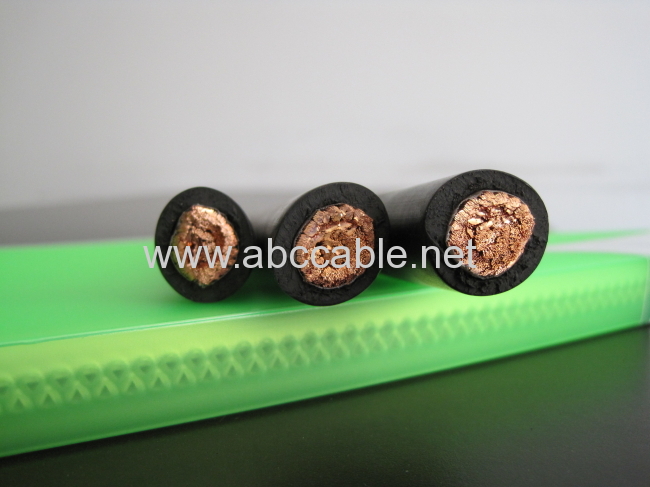

flexible copper wire

standard:

IEC/GB/DIN

origin:

China

Clients' feedback:

high flexibility and outsta...

Means of Transport:

Ocean,Land,Air

Packing:

standard wooden drum or ste...

Application:

Industrial

Insulation Material:

Rubber

Conductor Material:

Copper

type:

rubber cable

sheathed:

non-sheathed

core number:

single

color:

black/orange

1. Double Insulated

2. oil/solvents & chemicals resistant

3. Extra Flexible

4. Orange and Black Jacket

5. IEC,ISO,CQC,CCC

Welding Cables Double Insulated, Extra Flexible, Orange and Black Jacket

FEATURES : - Based on CENELEC HD 22-6 31, VDE 0282 ,IEC 245-6, IS 473, BS 638-4.

- Outstanding toughness & durability.

- High resistance to cuts , tears & abrasion.

- Resistance to oil , solvents and chemicals.

- Excellent ozone and weather resistant.

- Great Flexibility

- Abrasion resistance

- Good color retention

APPLICATIONS :

Welding : Designed for the secondary (high current) connection to automatic or hand – held metal arc welding electrodes. It is suitable for flexible use under rugged conditions, on assembly lines and conveyor systems, in machine tool and automatically operated line and spot welding machines.

Power : Earthing/return leads, power feeds to electrolytic plating process, Busbar connection, transformers, generators, aircraft servicing equipments etc. |

| CONSTRUCTION : |

- Conductor : High conductivity, bare annealed copper flexible conductor.

- Sheath : Double sheathed with specially developed thermoplastic Elastomer (TPR/TPE), outer layer is orange coloured.

|

| CURRENT RATING : The maximum current ratings of flexible welding cables for different duly cycles are based on an ambient air temperature of 25 C and a maximum conductor temperature of 90 C. The percentage duly cycles for various processes and applications are as follows: |

| 1 | Automobile Welding | : | up to 100% | | 2 | Semi-automatic welding | : | 30% to 85% | | 3 | Manual Welding | : | 0% to 60% | | 4 | Very intermittent or

Occasional Welding | : | up to 20% |

|

VOLTAGE DROP :When total cable lengths in excess of 15 mtrs., are involved , it may be necessary to use cables of larger cross section to ensure that the voltage drop is not excessive and welding currents are maintained at adequate levels. |

Cross -

Sectional area | Max.

Conductor

resistance

at 20°C | Nominal

Thickness

of

sheath | Min.

Overall

diameter | Max.

Overall

diameter | Current Ratings | | Welding Application | Non Welding

Application | | Duty Cycle | | | 100% | 85% | 60% | 30% | 20% | | | mm2 | ohm/km | mm | mm | mm | amp | amp | amp | amp | amp | amp | | 10 | 1.91 | 2 | 7.8 | 10 | 105 | 115 | 135 | 190 | 235 | 110 | | 16 | 1.21 | 2 | 9 | 11.5 | 135 | 145 | 175 | 245 | 302 | 138 | | 25 | 0.78 | 2 | 10 | 13 | 180 | 195 | 230 | 330 | 402 | 187 | | 35 | 0.554 | 2 | 11.5 | 14.5 | 225 | 245 | 290 | 410 | 503 | 233 | | 50 | 0.386 | 2.1 | 13 | 17 | 285 | 310 | 370 | 520 | 637 | 295 | | 70 | 0.272 | 2.4 | 15 | 19 | 355 | 385 | 460 | 650 | 794 | 372 | | 95 | 0.206 | 2.6 | 17.5 | 21.5 | 430 | 470 | 560 | 790 | 961 | 449 | | 120 | 0.161 | 2.8 | 19.5 | 24 | 500 | 540 | 650 | 910 | 1118 | 523 | | 150 | 0.129 | 3.0 | 21.5 | 26 | 580 | 620 | 740 | 1040 | 1297 | 608 | | 185 | 0.106 | 3.2 | 23 | 29 | 660 | 715 | 850 | 1200 | 1476 | 690 | | 240 | 0.0801 | 3.4 | 27.0 | 32.0 | 710 | 770 | 916 | 1296 | 1587 | 744 | | 300 | 0.0641 | 3.6 | 30.0 | 35.0 | 800 | 850 | 1035 | 1450 | 1790 | 840 | | 400 | 0.0486 | 3.8 | 33.0 | 39.0 | 925 | 1000 | 1195 | 1690 | 2070 | 970 |

|

Photo of the Welding Cables Double Insulated, Extra Flexible, Orange and Black Jacket

Related Search

Find more related products in following catalogs on Hisupplier.com